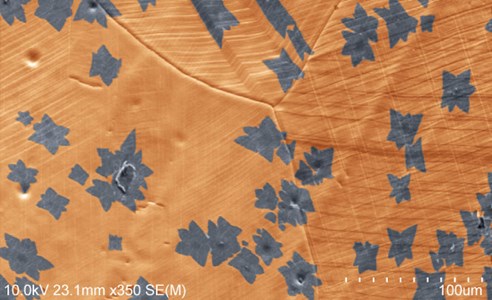

The large scale production of graphene for electronic devices relies on catalytic chemical vapor deposition (CVD). Therefore, main attention is dedicated to understand the mechanism of the graphene formation and also to control the growth. Nevertheless, in spite of many efforts put into the graphene CVD research, there are still many challenges to be solved. Cu or Ni are the most widely used catalysts due to their low cost, etchability and large grain size. Depending on the catalyst, two mechanisms of the graphene growth are proposed. In the case of Ni, the precursor is decomposed at the surface and carbon is dissolved in the metal. When the substrate is cooled down, the solubility of C in Ni decreases and graphene first segregates and then grows on Ni surface. Hence, it is very important to control the cooling conditions to reach a monolayer graphene (1-LG). On the other hand, in the case of copper catalyst, the carbon intermediate is not dissolved in the metal since the solubility of C in Cu is negligible even at a very high temperature. Instead, the carbon atoms form graphene directly on the surface already at high temperature, i.e. there is no need to precisely control the cooling of the metal. The CVD on copper is suggested to be surface mediated and self-limiting, once the monolayer is completed, the process does not propagate any more, since the catalytic Cu surface is blocked. Hence, only 1-LG should be formed by the Cu-catalyzed CVD, but in many cases small regions with double- or multilayers are observed. The mechanism of the formation of a multilayer regions is not well understood yet. These multilayer regions may impede the fabrication of graphene devices on large scale, because the multilayer areas disturb the uniformity of the graphene film.

-

Kalbac M., Frank O., Kavan L. Carbon 50(10), 3682-3687 (2012). DOI: 10.1016/j.carbon.2012.03.041

- Kalbac M., Frank O., Kong J., Sanchez-Yamagishi J., Watanabe K; Taniguchi T., Jarillo-Herrero P., Dresselhaus M.S. Large Variations of the Raman Signal in the Spectra of Twisted Bilayer Graphene on a BN Substrate. Journal of Physical Chemistry Letters 3(6), 796-799 (2012). DOI: 10.1021/jz300176a